Model No.: UNS NO7090, W.Nr.2.4632, GH90, GH4090, Nimonic 90

Brand: Jiangsu Xinhua

Place Of Origin: China

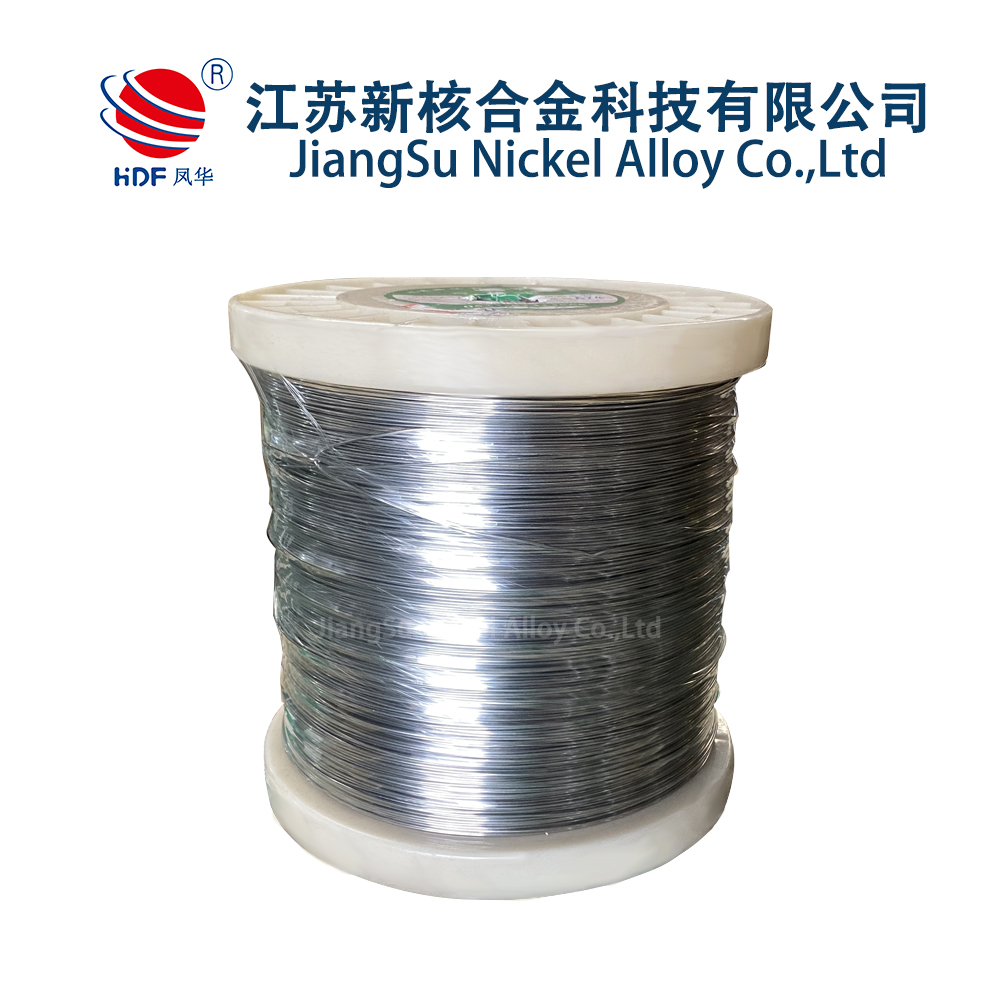

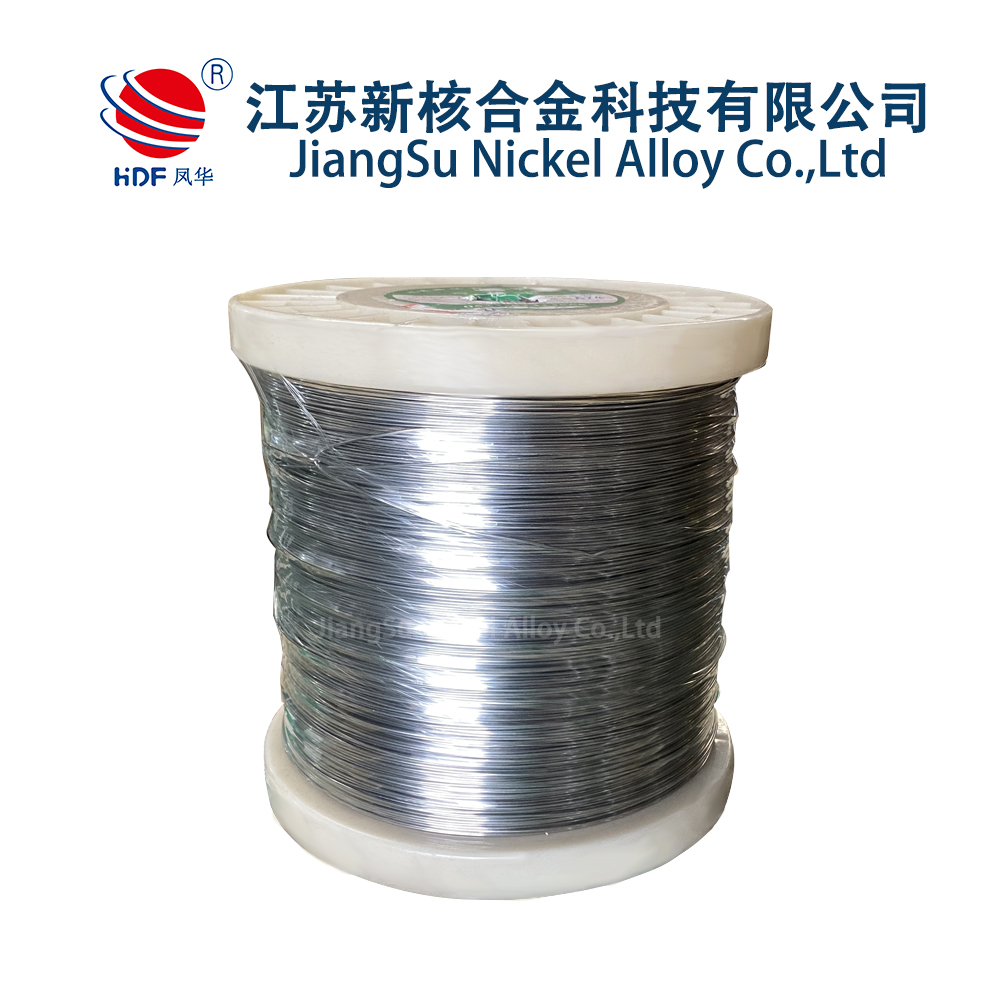

Species: Nickel Wire

Whether Powder: Not Powder

Packaging: standard export packing, plastic film inside, wooden pallets outside , choose the suitable packing

Productivity: 20 Metric tons per month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 20 Metric tons per month

Certificate: ISO9001

Port: SHANGHAI

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA

High-temperature nickel-based alloy GH90 is synthesized from nickel, chromium, cobalt, and small amounts of carbon, silicon, and other elements to provide excellent high-temperature performance and oxidation resistance. This alloy is capable of sustained operation in environments up to 850°C. Its high-temperature strength and creep resistance make it an indispensable material in industries such as aerospace, energy and chemicals.

FEATURE

1. High-temperature resistance: it can still maintain good mechanical properties in a high-temperature environment.

2. Excellent oxidation resistance: effectively prevent oxidation reaction at High temperature, which helps to extend the service life of the equipment. 3. Good thermal stability: able to maintain its structural stability in the environment of large temperature changes.

CHEMICAL COMPONENT

| Element | C | Cr | Ni | Co | Al | Ti | Mn |

| % | ≤0.13 | 18.0-21.0 | Bal | 15.0-21.0 | 1.0-2.0 | 2.0-3.0 | ≤0.4 |

| Element | Si | P | S | B | Cu | Fe | Zr |

| % | ≤0.8 | ≤0.02 | ≤0.015 | ≤0.2 | ≤0.2 | ≤1.5 | ≤1.5 |

MECHANICAL &PHYSICAL PROPERTIES

| Density | Melting | Elongation | Tensile strength | Yield strength |

| 8.2 g/cm³ | 1400°C | 8% | 820 MPa | 590 MPa |

APPLICATION AREA

1. Aerospace: Used in the manufacture of high-temperature components such as combustion chambers and turbine blades for aero-engines.

2. Energy industry: widely used in high temperature components for power plants, oil and gas extraction.

3. Chemical industry: used in high-temperature and high-pressure reactors, capable of resisting corrosion and high-temperature erosion.

4. Nuclear energy field: used in key components of nuclear reactors to ensure safety and durability.

5. Automotive industry: used in high-performance automobiles, such as turbochargers and other important components.