Min. Order:1 Kilogram

Transportation:Ocean,Land,Air,Express

Port:shanghai

Transportation: Ocean,Land,Air,Express

Port: shanghai

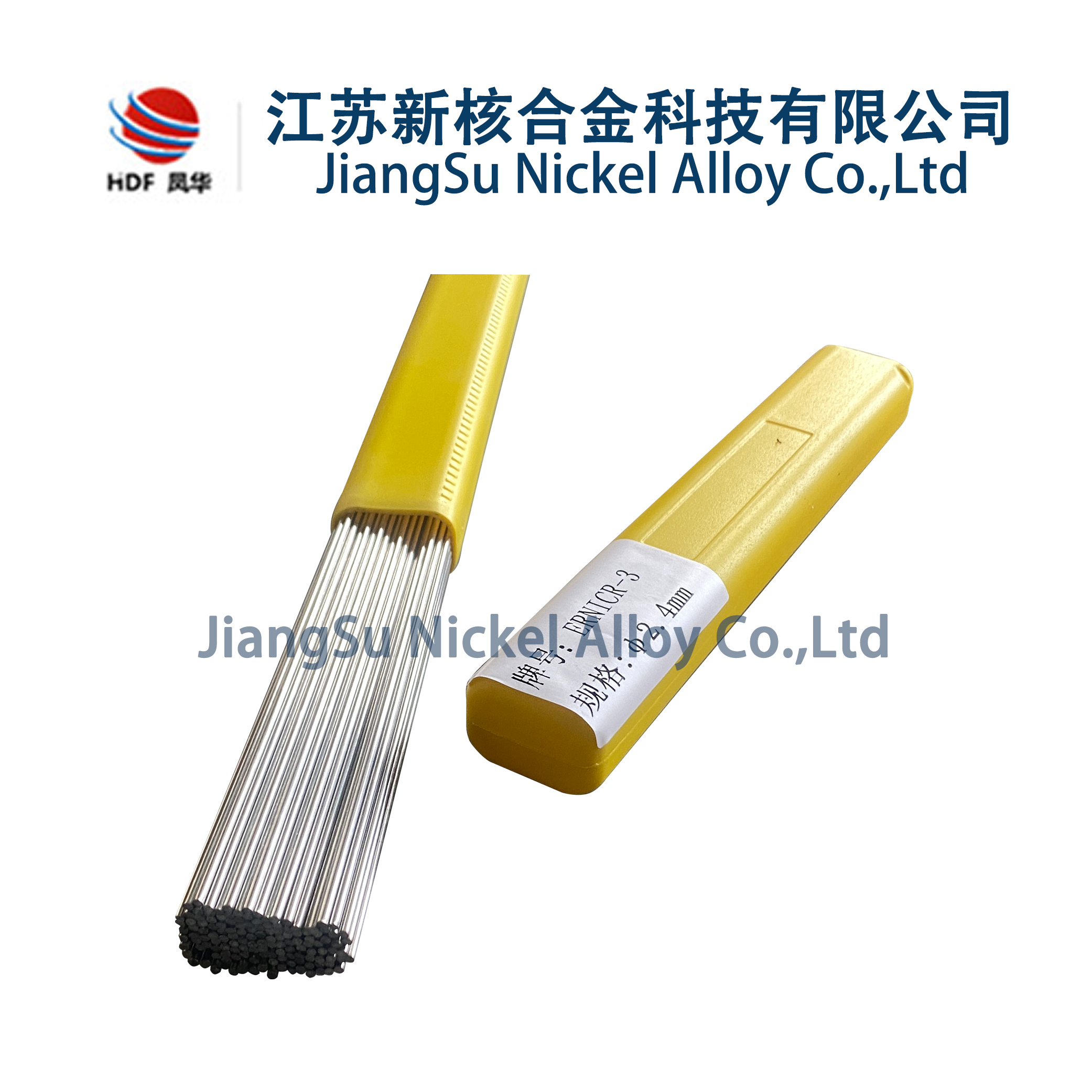

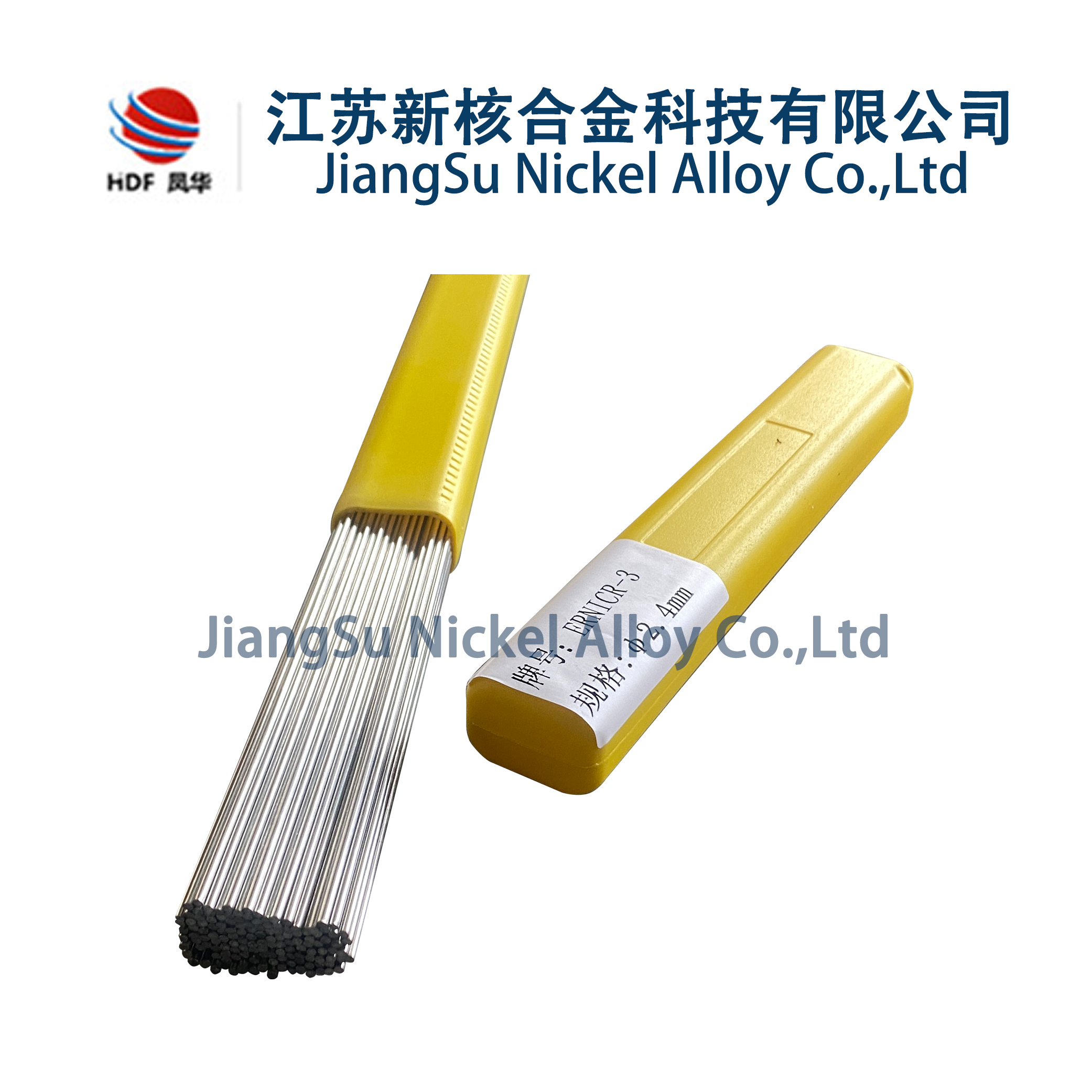

Ernicrmi-3 nickel base alloy welding wire is widely used in petrochemical industry because of its high Ni, Cr, Mo content and excellent properties. Metallurgy, aerospace and other fields. Its excellent combined mechanical properties, corrosion resistance and heat resistance make it the material of choice for welding critical components.

Application

Used for welding Inconel625, Inconel825, Monel400, etc., excellent performance in dissimilar material welding, can effectively connect nickel-based alloy and Stainless Steel, can also be used for carbon steel, low alloy steel and other welding. Applications from low temperatures to 540°.

Its chemical composition is nickel (65%-72%), chromium (20%-22.5%), molybdenum (8%-10%), iron (less than 0.5%), titanium (less than 0.75%), zirconium (less than 0.15%), copper (less than 0.5%) and other elements.

Key feature

1. Good weldability: the welding wire is easy to form a stable weld during the welding process, the weld is beautiful in shape, and the welding joint is high in strength.

2. Excellent corrosion resistance: The chromium and molybdenum elements in the welding wire make it have good corrosion resistance and can operate stably in harsh environments for a long time.

3. High temperature strength: The welding wire has a high temperature strength, suitable for high temperature working environment welding tasks.

4. Good processing performance: welding wire is easy to process into various shapes and sizes, convenient for use in practical applications.

Application area

ERNiCrMo-3 welding wire is widely used in petrochemical, aerospace, shipbuilding, electric power and other fields. Specifically, it is mainly used for welding tasks in the following aspects:

1. Petrochemical equipment: Petrochemical equipment is often required to operate in high temperature, high pressure and corrosive environments, ERNiCrMo-3 welding wire because of its good corrosion resistance and high temperature strength is the preferred welding material.

2. Aerospace devices: Aerospace devices have very high requirements for welding quality, and ERNiCrMo-3 welding wire can meet these requirements to ensure the safety and reliability of the device.

3. Shipbuilding industry: Shipbuilding industry involves a lot of metal welding work, ERNiCrMo-3 welding wire because of its good welding performance and corrosion resistance and is widely used in hull, Marine equipment and other parts of the welding.

4. Power industry: In the power industry, ERNiCrMo-3 welding wire is often used in the manufacturing and maintenance process of power equipment such as generators and transformers to ensure the safe operation of equipment.