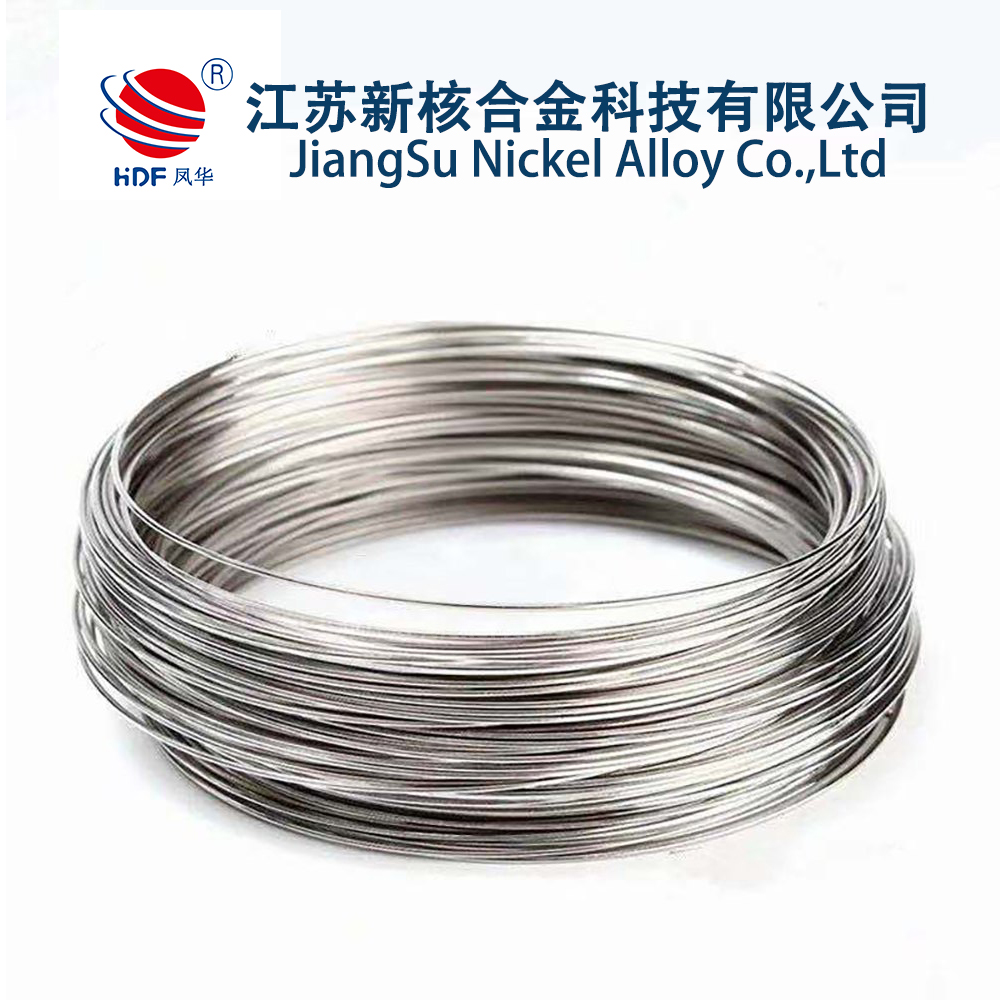

Model No.: W.Nr.2.4816, UNS NO6600, GH600, NS3102, NiCr15Fe, NA14, NC15FE

Brand: HDF

Place Of Origin: China

Species: Nickel Wire

Whether Powder: Not Powder

Packaging: standard export packing, plastic film inside, wooden pallets outside , choose the suitable packing

Productivity: 20 metric tons per month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 20 metric tons per month

Certificate: ISO 9001

Port: shanghai

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA

Inconel 600 alloy is a nickel-chromium-iron based alloy with good High temperature corrosion and oxidation resistance, excellent hot and cold processing and welding performance, satisfactory thermal strength and high plasticity below 700°C. Its excellent physical and chemical properties and mechanical properties make it an indispensable and important material in modern industry.

FEATURE

Corrosion resistance: Inconel 600 has good resistance to a variety of corrosive media, including oxidizing acids and chlorides.

High temperature resistance: It can be used for a long time at temperatures up to 1093°C and is not easily oxidized or loses strength at extreme high temperatures.

Good mechanical properties: It has good strength, toughness and ductility under low and high temperature conditions.

Weldability: It is easy to weld and process, suitable for a variety of manufacturing processes.

CHEMICAL COMPONENT

| Element | Ni | Cr | Fe | C | Mn | Si | Cu | S |

| Min | 72 | 14 | 6.0 | - | - | - | - | - |

| Max | - | 17 | 10 | 0.15 | 1.0 | 0.5 | 0.5 | 0.015 |

PHYSICAL PROPERTIES

| Density | Melting | Tensile strength | Yield strength | Elongation |

| 8.42 g/cm³ | 1354-1413°C | 550 MPa | 240 MPa | 40% |

APPLICATION AREA

Aerospace: used to manufacture high-temperature parts of aircraft engines, such as turbine blades, combustion chambers and gas turbines.

Petrochemical: used to manufacture high-temperature and high-pressure containers, heat exchangers, pipes and valves.

Nuclear energy industry: used to manufacture control rods, heaters and protective shells in nuclear reactors.

Chemical industry: used to manufacture equipment and parts resistant to high temperatures and corrosive media.

Power industry: used to manufacture high-temperature parts such as boiler pipes and turbine blades.