Payment Type:L/C,T/T,Paypal

Incoterm:FOB,CFR,CIF,EXW,FCA

Transportation:Ocean,Land

Port:SHANGHAI

Model No.: UNS NO7090, W.Nr.2.4632, GH4090, GH90, Nimonic 90

Brand: HDF

Place Of Origin: China

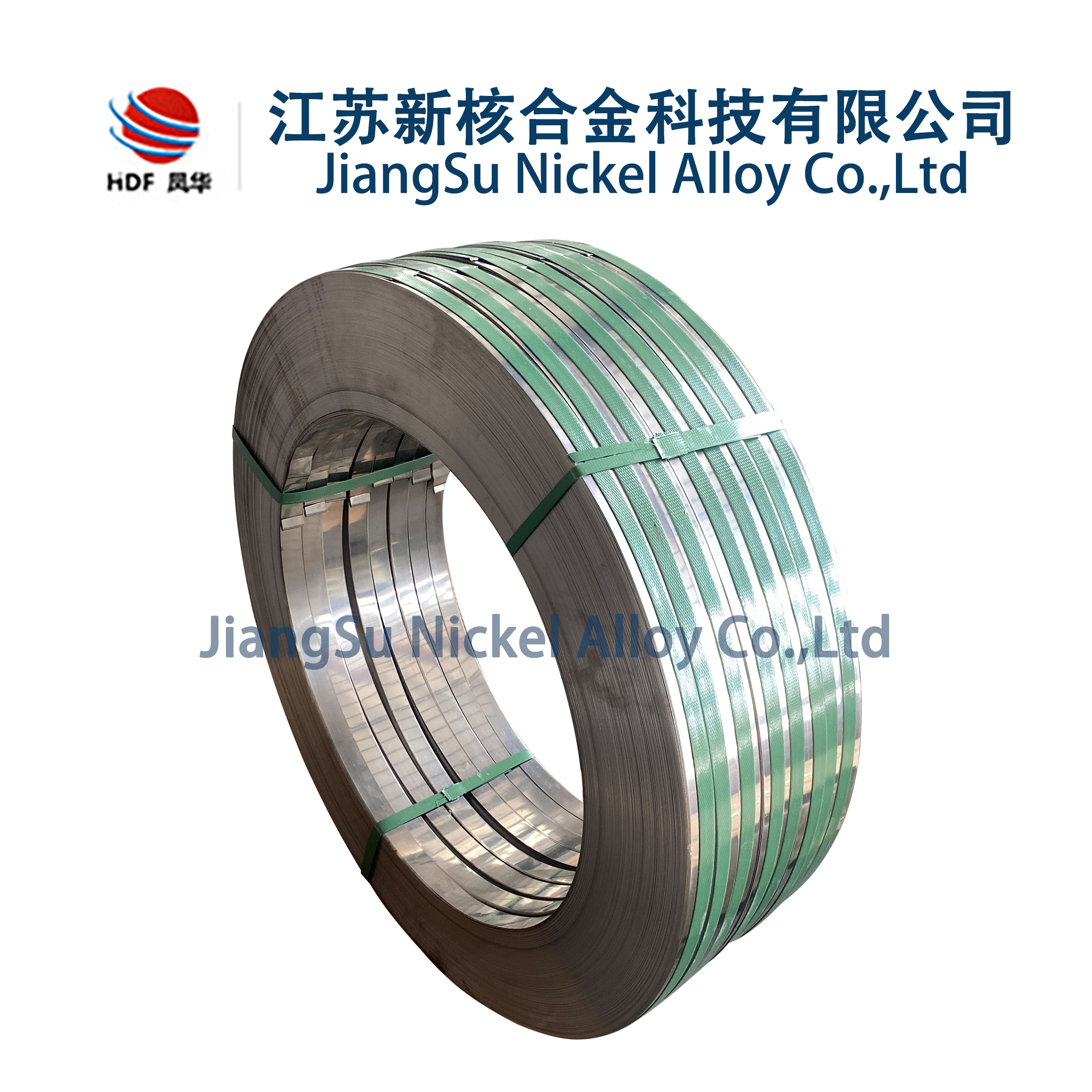

Species: Nickel Strip

Whether Powder: Not Powder

Packaging: standard export packing, plastic film inside, wooden pallets outside , choose the suitable packing

Productivity: 20 Metric tons per month

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 20 Metric tons per month

Certificate: ISO9001

Port: SHANGHAI

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA

| Element | Cr | Co | C | Ni | Al | Ti | Mn | Si | P | S | B | Cu | Fe | Zr |

| % | 18.0-21.0 | 15.0-21.0 | ≤0.13 | Bal | 1.0-2.0 | 2.0-3.0 | ≤0.4 | ≤0.8 | ≤0.02 | ≤0.015 | ≤0.20 | ≤0.20 | ≤1.50 | ≤1.50 |

| Density | Melting | Tensile strength | Yield strength | Elongation |

| 8.2 g/cm³ | 1400°C | 820 MPa | 590 MPa | 8% |