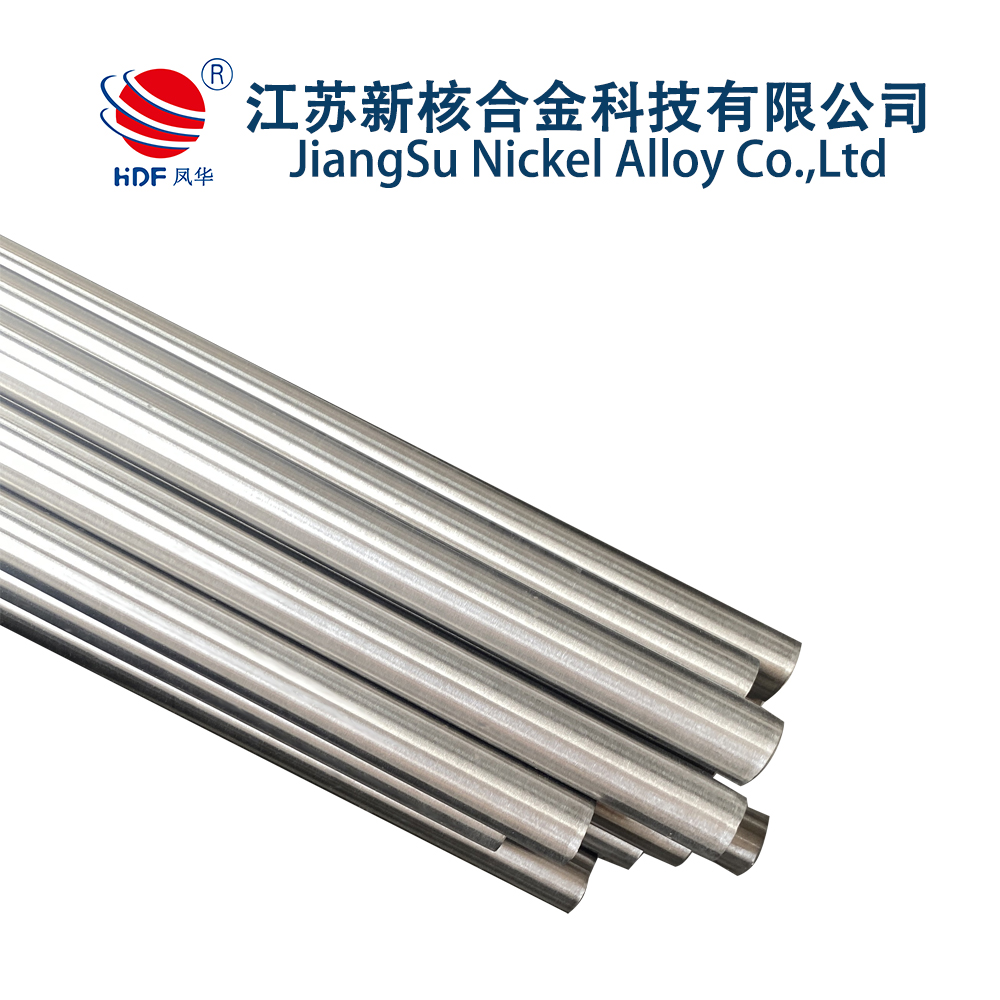

Model No.: GH5188, UNS N30188, W.Nr.2.4683, Haynes 188

Brand: hdf

Place Of Origin: China

Species: Nickel Bar

Whether Powder: Not Powder

Packaging: Standard export packaging, wooden box packaging

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Certificate: iso9001

Port: SHANGHAI

Payment Type: L/C,T/T,Paypal

Incoterm: FOB

GH5188 is a Co-Ni-Cr based solid solution strengthened deformable high-temperature alloy, designed for use in high-temperature environments below 1100℃. Due to its outstanding high-temperature performance and weldability, GH5188 is widely used in high-temperature components in the aerospace, aviation and energy industries. GH5188 not only has strong mechanical properties, but also performs excellently in high-temperature and corrosive environments, maintaining superior working performance under harsh conditions.

FEATURE

1. Excellent high-temperature strength

In extremely high-temperature environments, GH5188 cobalt-based alloy can maintain outstanding strength and stability, making it an ideal choice for high-temperature applications.

2. Good oxidation and corrosion resistance

It demonstrates strong resistance in both oxidative atmospheres and corrosive media, ensuring the long-term reliability of the material.

3. Superior wear resistance

Under conditions of friction and wear, GH5188 cobalt-based alloy exhibits exceptional durability, reducing maintenance and replacement costs for equipment.

CHEMICAL COMPONENT

| Element | Ni | Cr | Fe | W | Cu | Co | C | Mn | Si | S | P |

| Min | 20.0 | 20.0 | - | 13.0 | - | Bal | 0.05 | - | 0.2 | - | - |

| Max | 24.0 | 24.0 | 3.0 | 16.0 | 0.07 | 0.15 | 1.25 | 0.5 | 0.15 | 0.02 |

PHYSICAL & MECHANICAL

| Density | Melting | Tensile strength | Yield strength | Elongation |

| 9.09 g/cm³ | 1300-1360°C | 860 MPa | 380 MPa | 45% |

APPLICATION

1. Aerospace

The high-temperature components used in manufacturing engines, such as turbine blades and combustion chambers, provide strong support for the efficient operation of aircraft.

2. Energy sector

It plays a crucial role in equipment like gas turbines and steam turbines, improving the efficiency of energy conversion.

3. Industrial manufacturing

In fields such as mold manufacturing and tool manufacturing, its wear-resistant properties significantly enhance the service life and efficiency of tools.