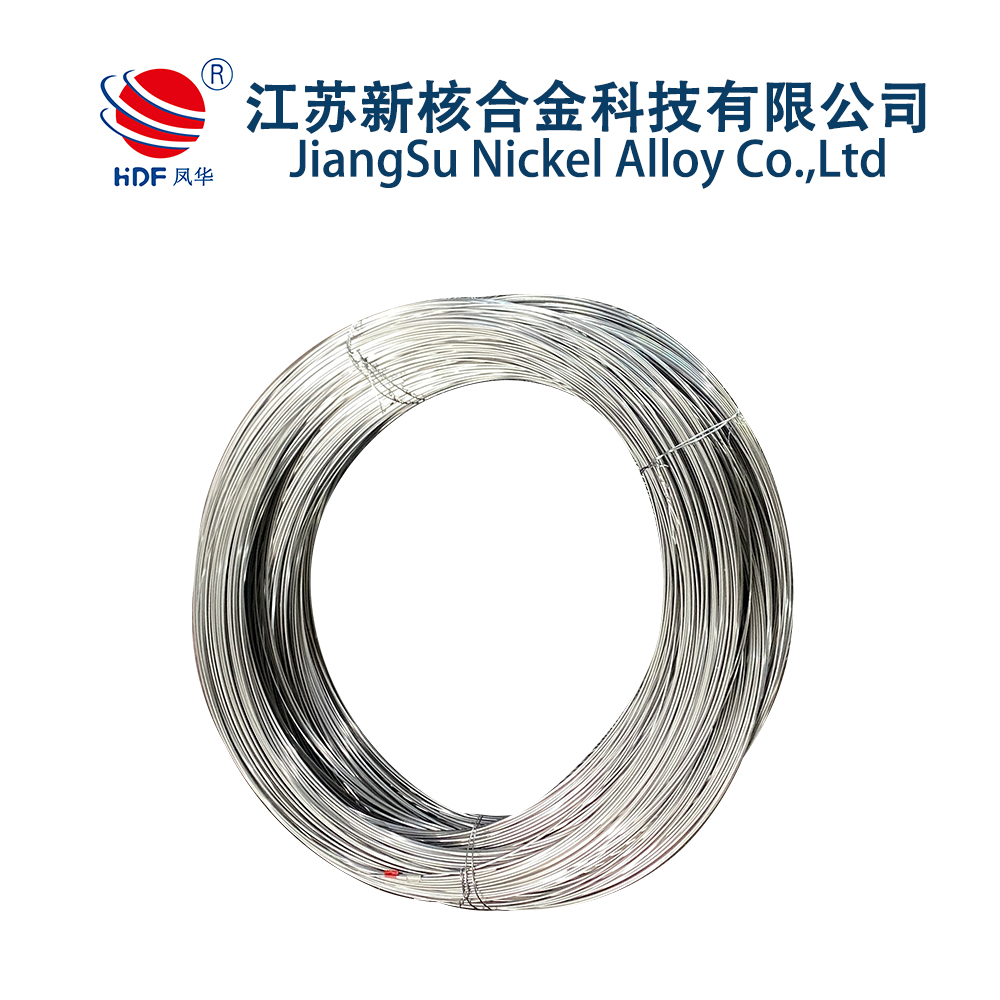

Model No.: MP35N, UNS R30035

Brand: hdf

Place Of Origin: China

Species: Nickel Wire

Whether Powder: Not Powder

Packaging: Standard export packaging, wooden box packaging

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Certificate: iso9001

Port: SHANGHAI

Payment Type: L/C,T/T,Paypal

Incoterm: FOB

MP35N is a precipitation-hardening nickel cobalt-based alloy with a unique combination of properties - ultra-high strength, toughness, ductility and excellent corrosion resistance. MP35N is resistant to corrosion in hydrogen sulfide, brine and other chloride solutions. It also has excellent crack and stress corrosion cracking resistance in seawater and other harsh environments. The four alloying elements in MP35N are the basis for the corrosion resistance of almost all commonly used stainless steels, nickel and cobalt-based alloys in industry. This alloy is resistant to corrosion in hydrogen sulfide, brine and other chloride solutions as well as inorganic acids (nitric acid, hydrochloric acid and sulfuric acid).

MP35N is suitable for applications that require a high combination of high strength, high modulus value and good corrosion resistance.

FEATURE

1. It has high strength at ambient temperature.

2. It features good ductility and excellent mechanical properties.

3. It has outstanding resistance to hydrogen sulfide corrosion.

4. It has excellent resistance to seawater cracking and stress corrosion cracking.

CHEMICAL COMPONENT

| Element | C | P | Si | Ni | Co | Mn | S | Cr | Mo | Ti | Fe |

| Min | - | - | - | 33.0 | Bal | - | - | 19.0 | 9.0 | - | - |

| Max | 0.03 | 0.015 | 0.15 | 3.7 | 0.15 | 0.01 | 21.0 | 10.5 | 1.0 | 1.0 |

PHYSICAL & MECHANICAL PROPERTIES

| Density | Melting | Tensile strength | Yield strength | Elongation |

| 8.43 g/cm³ | 1440°C | 1380 MPa | 1240 MPa | 10% |

APPLICATION

1. Medical equipment: Used for manufacturing high-performance components of medical equipment, such as orthopedic implants, etc.

2. Chemical industry: Used for corrosion-resistant chemical equipment and components, especially in situations that require withstanding high pressure and

High temperature.

3. Oil and gas wells: Used for manufacturing components such as oil well drill pipes and valves to withstand harsh underground environments.

4. Instrument components: Used for manufacturing instrument components that require high strength and high corrosion resistance.