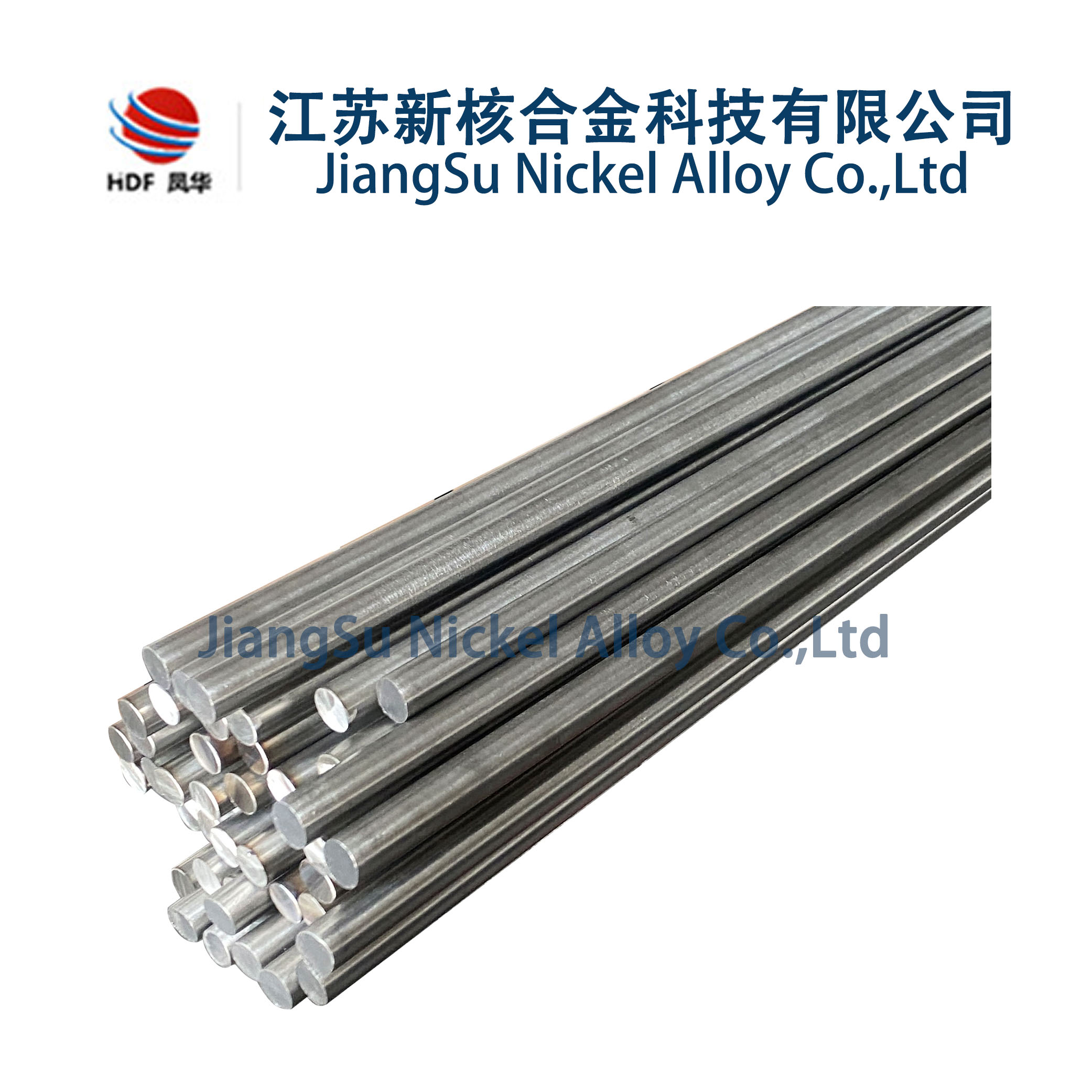

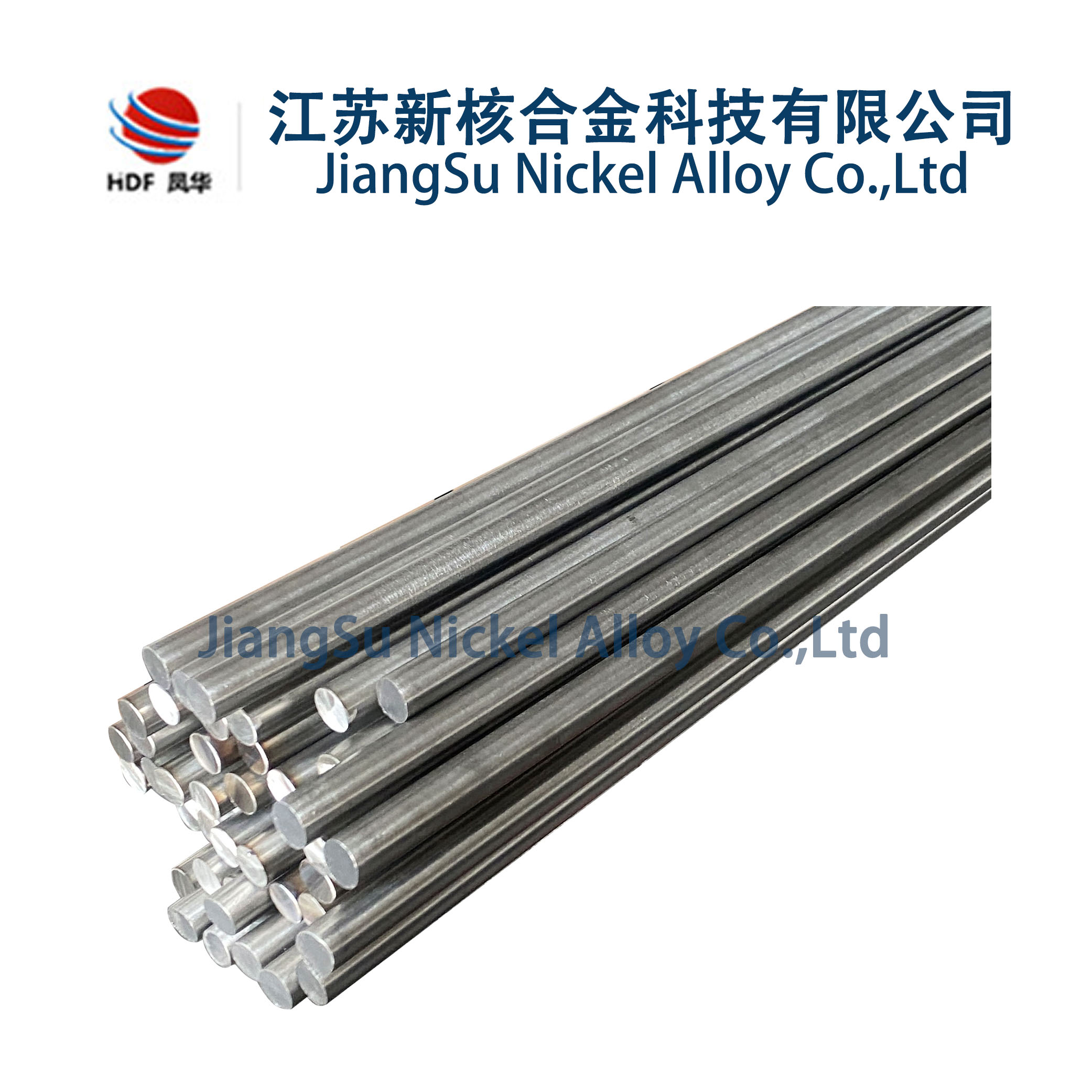

Model No.: UNS NO7263, W.Nr.2.4650, Nimonic 263

Brand: HDF

Packaging: standard export packing

Productivity: 20 Metric tons per month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 20 Metric tons per month

Certificate: ISO9001

Port: SHANGHAI

Payment Type: L/C,T/T

Incoterm: FOB

Nimonic 263 (UNS N07263/W. Nr. 2.4650) is a high-performance nickel-based superalloy that plays an important role in the aerospace and energy fields due to its excellent high-temperature performance and good processing characteristics. Its unique chemical composition and sophisticated heat treatment process enable it to exhibit excellent performance in extreme environments, making it an ideal choice for high-temperature and high-stress applications.

FEATURE

1. Heat resistance: It has good stability at high temperatures, can work for a long time at temperatures up to 750°C, and can maintain good performance even at higher temperatures.

2. Corrosion resistance: It performs well in acid and alkali media, with good corrosion resistance and oxidation resistance.

3. Mechanical properties: It has excellent strength and toughness, and can still maintain high mechanical properties at high temperatures.

CHEMICAL COMPONENT

| Element | Ni | Co | Cr | Mo | Ti | Fe | Mn | Al | Si | Cu | C | B | S |

| % | Bal | 19-21 | 19-21 | 5.60-6.10 | 1.90-2.40 | 0.70 | 0.60 | 0.60 | 0.40 | 0.20 | 0.40-0.80 | 0.005 | 0.007 |

PHYSICAL & MECHANICAL PROPERTIES

| Density | Melting | Tensile strength | Yield strength | Elongation |

| 8.36 g/cm³ | 1340-1380°C | 940 MPa | 550 MPa | 39% |

APPLICATION AREA

1. Aviation turbine engine parts

2. Land-based turbine parts

3. Various manufacturing parts requiring High temperature strength and corrosion resistance