Model No.: inconel 625

Place Of Origin: China

Certificate: ISO9001/ROHS/BV

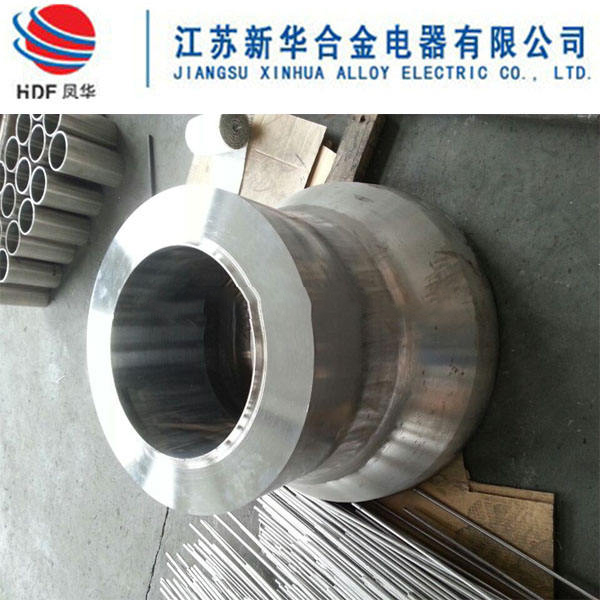

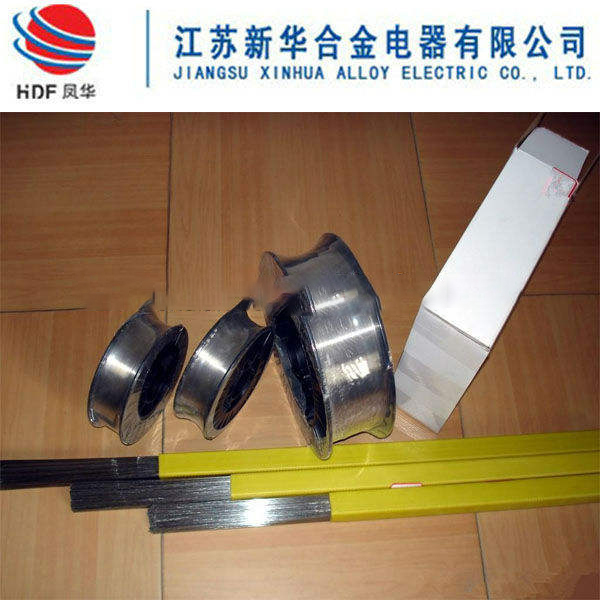

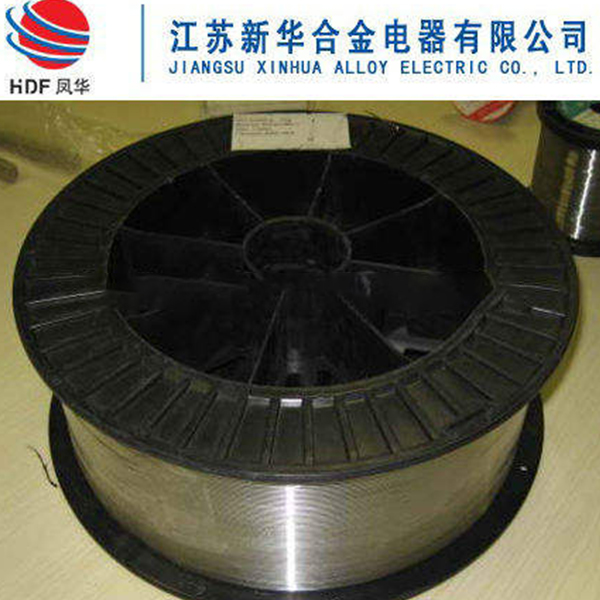

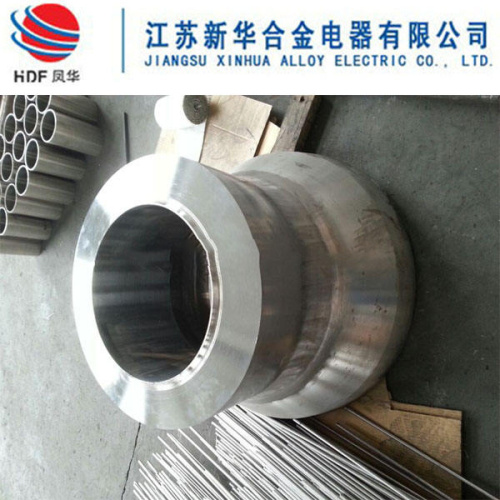

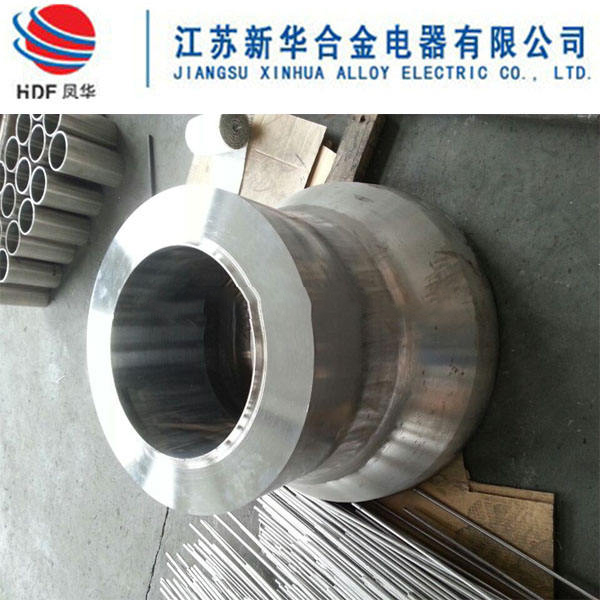

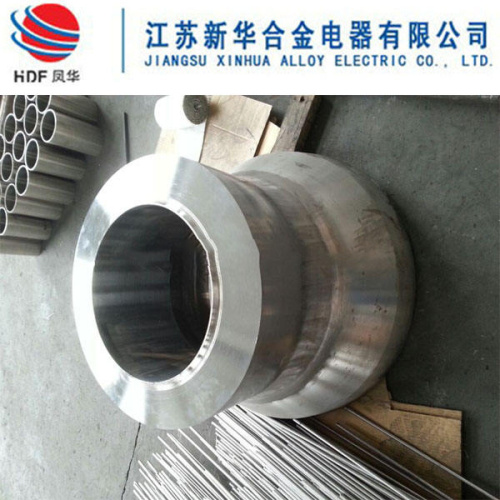

Shape: wire/strip/ribbon/sheet/bar/pipe

Chemical Composition: 58% min nickel, 20

W.Nr: 2.4856

Property: Alloy 625 Welding Wire inconel

Application: Chemical processing equipme

Material: nickel-chromium-molybdenum

Grade: Alloy 625 Welding Wire

UNS: N06625

Standard: ASTM/AISI/ASME/GB/DIN

Packaging: Standard seaworthy package(wooden boxes package,pvc package, and other package).or as buyers requirement

Transportation: Ocean

Place of Origin: china

Supply Ability: 10 Metric Ton/Metric Tons per Month

Port: Shanghai

Alloy 625 Welding Wire inconel 625

Alloy 625 is used for the welding of Inconel® alloy 625, Incoloy® alloy 825, Inco® alloy 25-6MO, and other molybdenum-containing stainless steels. This filler metal is also used for surfacing of steel, for welding nickel steels, and for welding various corrosion-resistant alloys such as alloy 20. The weld metal of Alloy 625 has high strength over a broad temperature range and has exceptional corrosion resistance, including resistance to localized attack such as pitting and crevice corrosion. Alloy 625 is useful for many dissimilar joints involving Inconel® and Incoloy® alloys, carbon steels, low-alloy steels, and stainless steels.

AWS 5.14 AWS ERNiCrMo-3

ASME SFA 5.14 UNS N06625.

inconel 625 Chemical Composition

| AWS Classification | UNS Number | Weight Percent | ||||||||||||||

| C | Mn | Fe | P | S | Si | Cu | Ni | Co | Al | Ti | Cr | Nb(Cb) Plus Ta | Mo | |||

| ERNiCrMo-3a | N06625 | 0.10 | 0.50 | 5.0 | 0.02 | 0.015 | 0.50 | 0.50 | 58.0min |

| 0.40 | 0.40 | 20.0-23.0 | 3.15-4.15 | 8.0-10.0 | |