Min. Order:1 Kilogram

Transportation:Ocean,Land,Air,Express

Port:shanghai

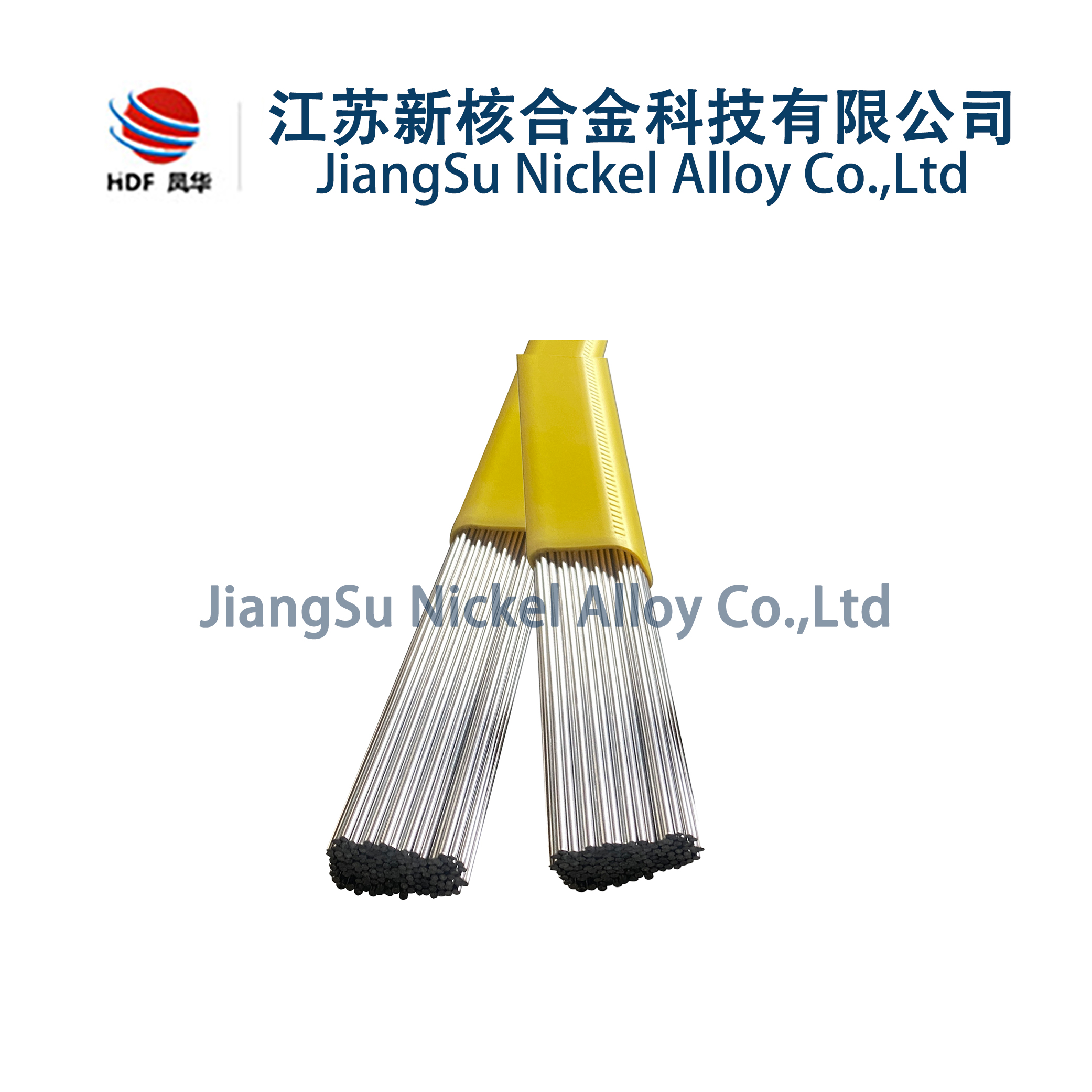

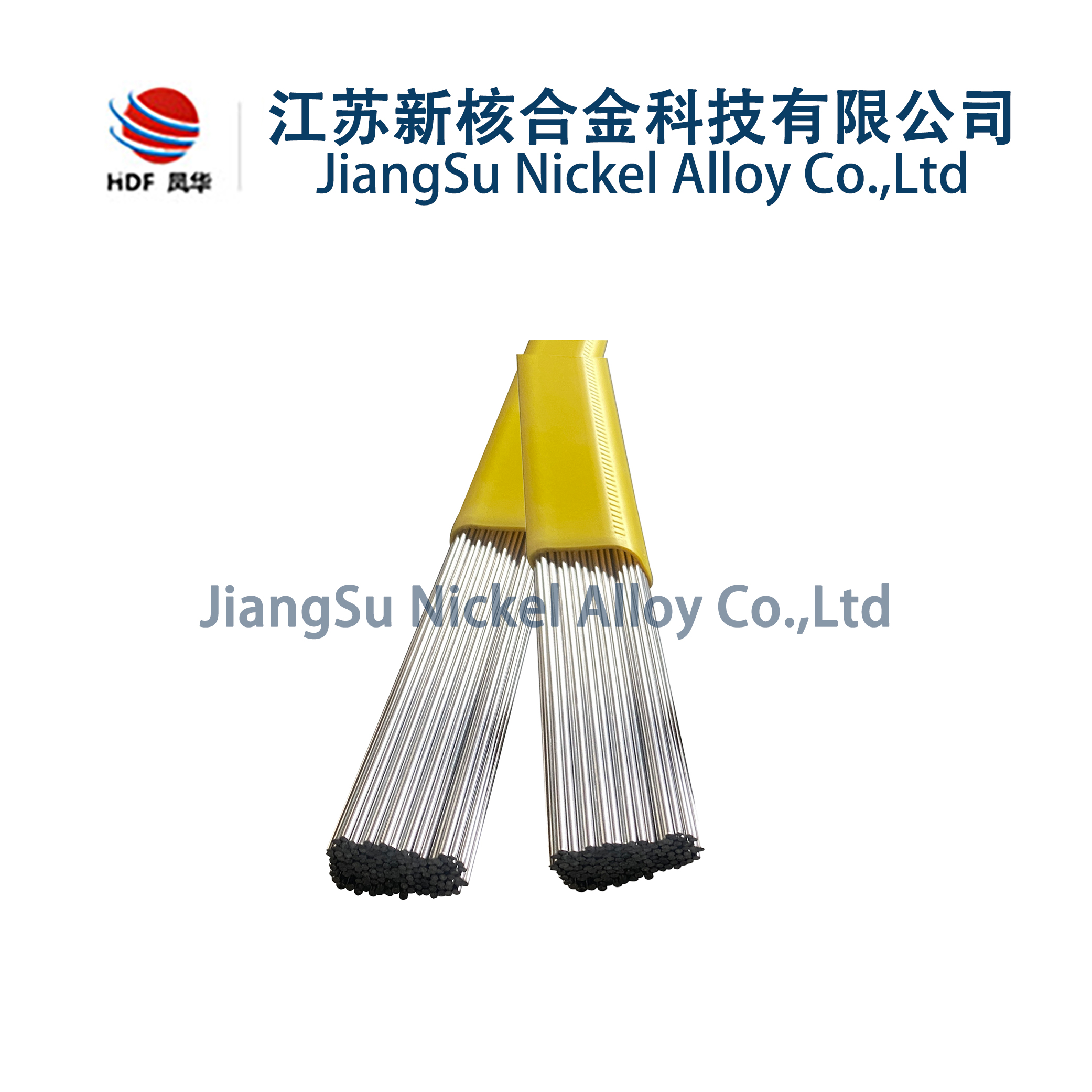

Packaging: standard export packing, plastic film inside, wooden pallets outside , choose the suitable packing

Transportation: Ocean,Land,Air,Express

Supply Ability: 20 Metric Ton/Metric Tons per Month

Port: shanghai

Ernicrmi-4 Nickel-based alloy welding wire has corrosion resistance and High temperature strength The coating metal has good mechanical properties and a variety of corrosive media has good resistance to spot and gap corrosion, arc stable point, beautiful forming, good flow, with excellent welding process performance. Widely used in nickel-based alloy, carbon steel welding, the advantages of corrosion resistance, high temperature strength, good welding performance.

Chemical component

| Alloy | Ni | C | Si | S | P | Mn | Fe | Cr | Mo | Cu | W | V |

| % | ≥5.0 | ≤0.02 | ≤0.08 | ≤0.015 | ≤0.02 | ≤1.0 | 4.0-7.0 | 14.5-16.5 | 15-17 | ≤0.50 | ≤3.0-4.5 | ≤0.13 |

Material advantage

1. Excellent corrosion resistance: Good resistance to pitting and crevice corrosion in a variety of corrosive media.

2. High temperature strength: it can still maintain high strength and mechanical properties under high temperature environment.

3. Good melting and welding performance: the melting speed is moderate, will not produce too much slag or pores and other defects, to ensure the quality of the weld.

4. Arc stability: beautiful shape, good flow of molten iron, with excellent welding process performance.

Application area

ERNiCrMo-4 is mainly used for welding Hastelloy C276 and other nickel-chromium-molybdenum based materials. Its corrosion resistance and high durability make it widely used in:

Chemical and petrochemical industries

marine environment

electrical power generating system

Pulp and paper processing