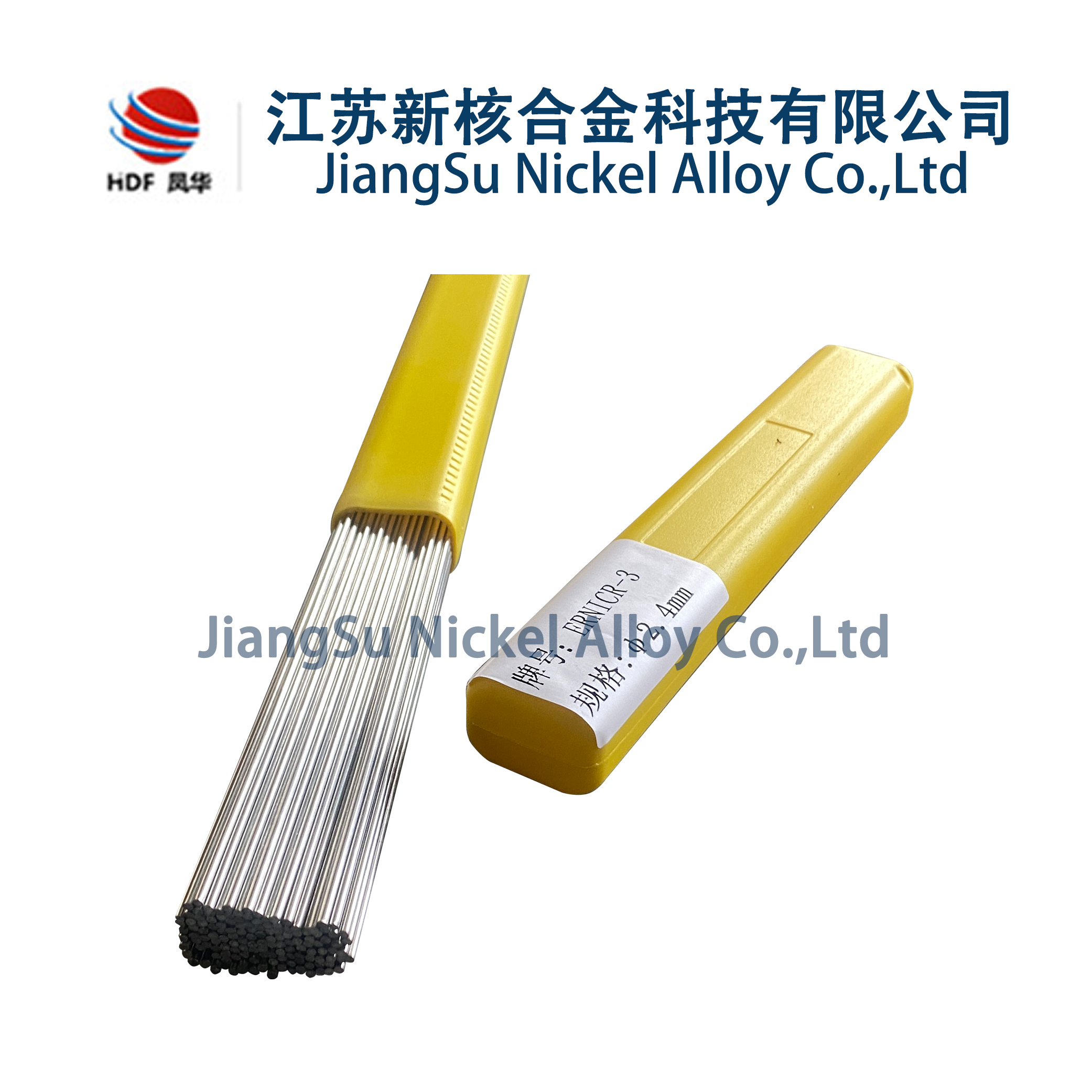

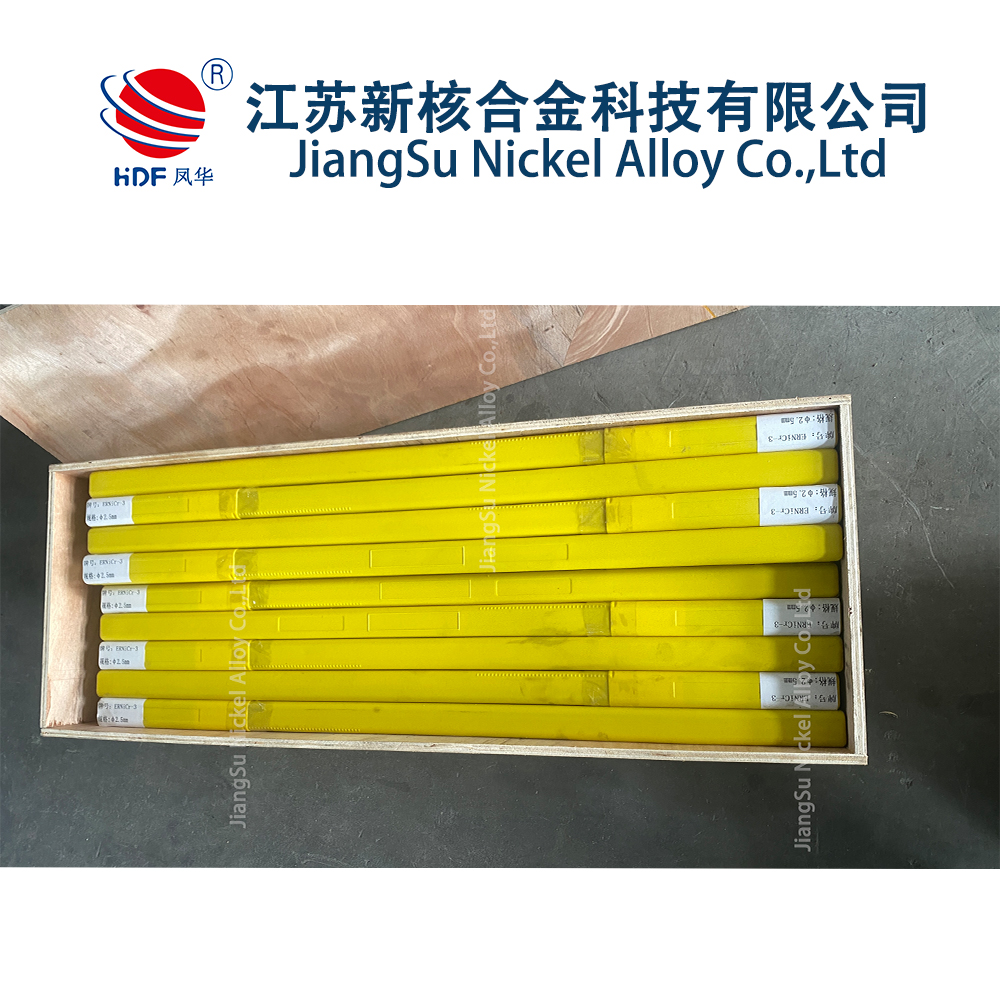

Model No.: UNS NO6082, W.Nr.2.4621, ERNiCr-3, NA35, NiCr20Mn3Nb

Brand: Jiangsu Xinhua

Packaging: standard export packing, plastic film inside, wooden pallets outside , choose the suitable packing

Productivity: 20 Metric tons per month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 20 Metric tons per month

Certificate: ISO9001

Port: SHANGHAI

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA

Click the link above to learn more about the products

ERNiCr-3 is a nickel-chromium-iron nickel-based welding wire. The cladding metal has good mechanical properties, good corrosion resistance, oxidation resistance, and high creep strength. The arc is stable, the shape is beautiful, the molten iron has good fluidity, and it has excellent welding process performance.

FEATURE

- Excellent corrosion resistance

- High strength and toughness at high temperatures.

- Can weld a variety of materials

- Welds are beautiful, smooth and free of pores.

- Sensitivity to hot cracking is also low at low temperatures.

CHEMICAL COMPONTENT

| Element | Cr | Ni | Mn | Fe | C | Si |

| % | 18.0-22.0 | ≥ 67 | 2.5-3.5 | ≤ 3.0 | ≤ 0.1 | ≤ 0.05 |

| Element | P | Cu | S | Nb+Ta | Ti | Co |

| % | ≤ 0.03 | ≤ 0.5 | ≤ 0.015 | 2.0-3.0 | ≤ 0.75 | ≤ 0.15 |

APPLICATION AREA

- In the aerospace field, ERNiCr-3 is often used for welding key parts such as aircraft engine components and heat exchangers. Its excellent High temperature performance and creep resistance can ensure structural stability and reliability under extreme temperature changes and high stress environments.

- In the petrochemical industry, it is used to weld equipment and pipelines in contact with corrosive media, such as in harsh environments such as hydrochloric acid and sulfuric acid, showing excellent corrosion resistance and effectively extending the service life of the equipment.

- In the energy and power field, ERNiCr-3 can be used to weld nuclear reactor components, natural gas processing equipment, etc. Under high temperature and high pressure conditions, it ensures the quality and performance of the welded joints and ensures the safe and stable operation of the equipment.