Model No.: UNS NO6052, W.NR.2.4831, ERNiCrMo-3, NA43, NiCr21Mo9Nb

Brand: Jiangsu Xinhua

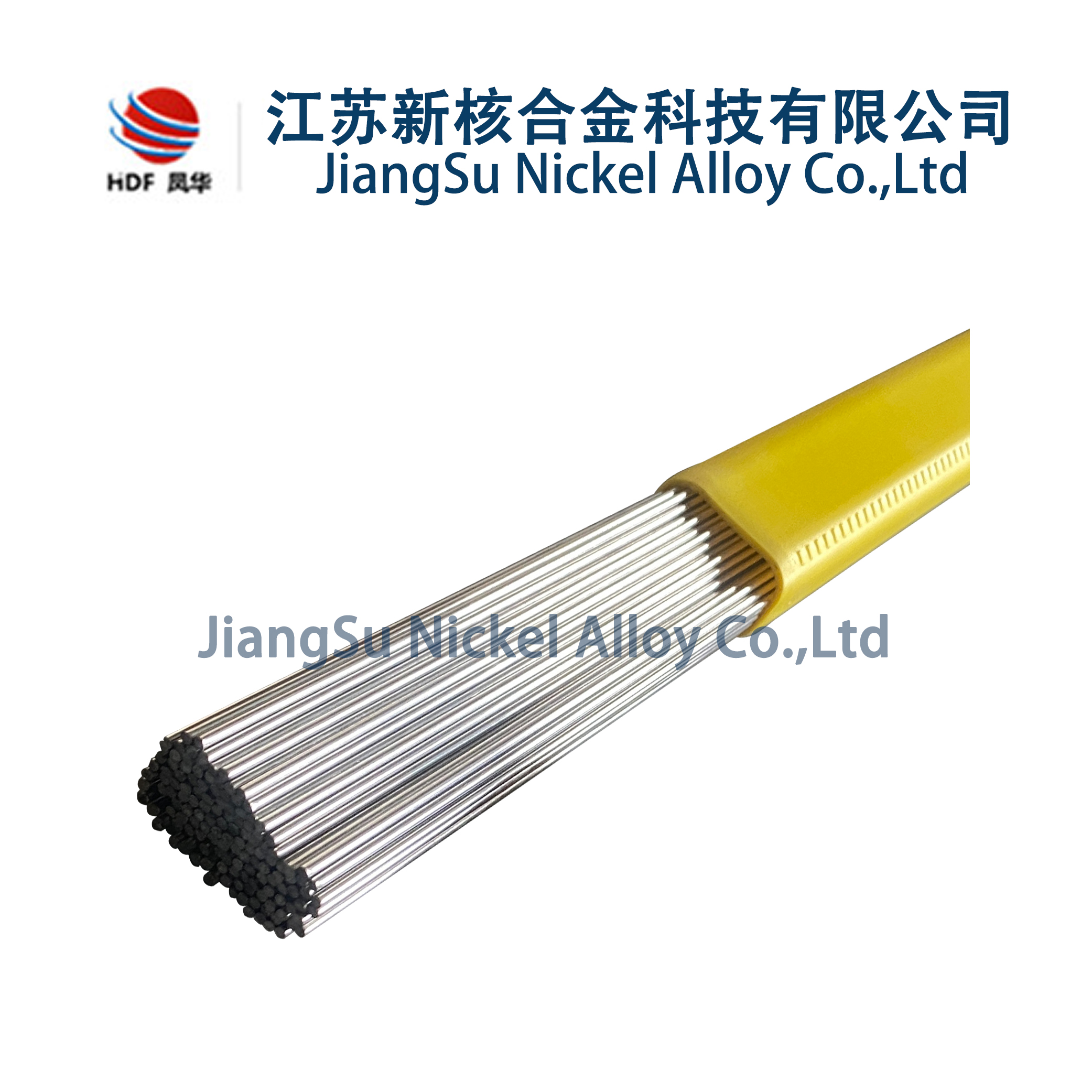

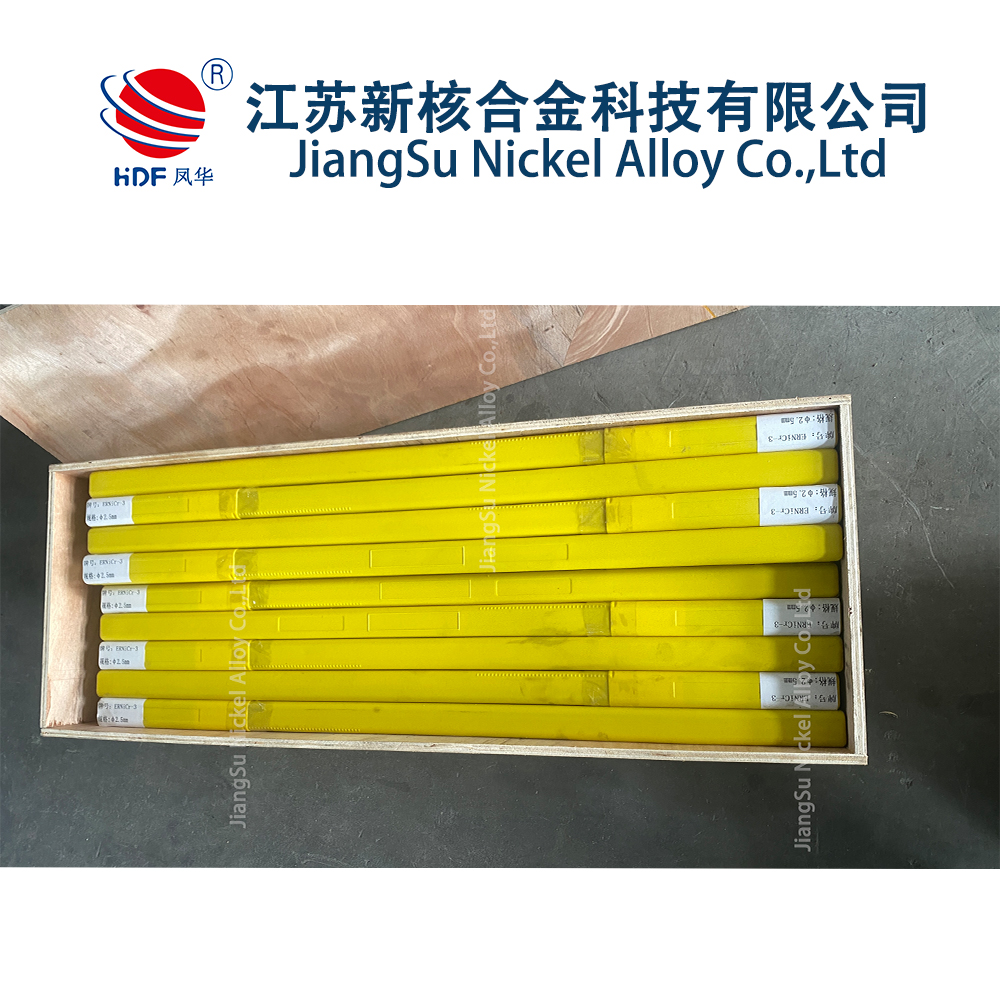

Packaging: standard export packing, plastic film inside, wooden pallets outside , choose the suitable packing

Productivity: 20 Metric tons per month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 20 Metric tons per month

Certificate: ISO9001

Port: SHANGHAI

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA

Click the link above to learn more about the products

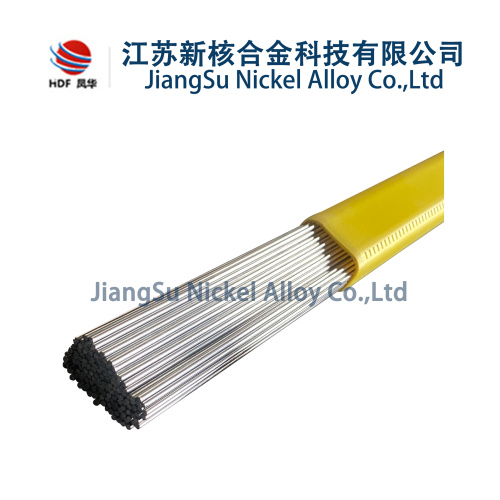

ERNiCrMo-3 nickel-based alloy welding wire is widely used in petrochemical, metallurgy, aerospace and other fields due to its high nickel, chromium and molybdenum content and excellent performance. Its excellent comprehensive mechanical properties and corrosion resistance make it the preferred material for welding key components.

ERNiCrMO-3 welding wire is suitable for a variety of advanced welding methods. Among them, metal arc welding (MIG) can improve welding efficiency, especially for welding thicker materials; tungsten inert gas welding (TIG) is suitable for precision welding, which can ensure beautiful and high-quality welds; in addition, it is also suitable for submerged arc welding, which can effectively control the quality of welds in mass production in combination with special fluxes such as INCOFLUX 7.

It is suitable for welding nickel-chromium-molybdenum alloys, such as Inconel 625, Inconl825, Monel 400, and can also be used for welding and surface surfacing of nickel-based alloys and Stainless Steel dissimilar materials, as well as welding with carbon steel, low alloy steel, etc.

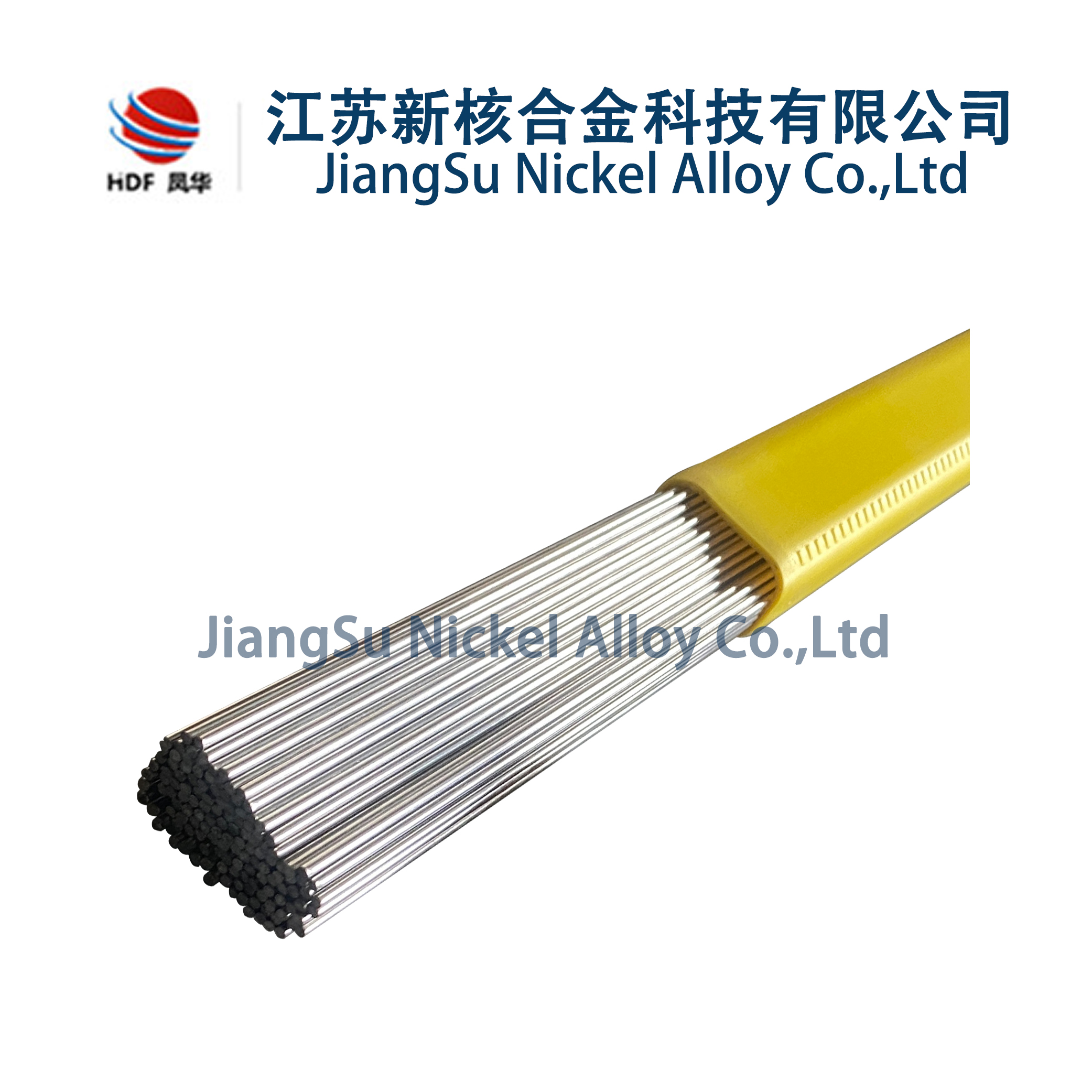

FEATURE

- Good weldability

- Excellent corrosion resistance

- High High temperature strength

- Good processing performance

- Stable arc, beautiful shape, good molten iron fluidity

CHEMICAL COMPONTENT

| Element | Ni | C | Mn | Fe | S | Cu |

| % | ≥64 | ≤0.1 | ≤0.5 | ≤1.0 | ≤0.015 | ≤0.50 |

| Element | Si | Al | Cr | Ti | Nb | Mo |

| % | ≤0.50 | ≤0.40 | 22.0-23.0 | ≤0.40 | 3.6-4.5 | 9.2-10.0 |

APPLICATION AREA

- Petrochemical equipment: Petrochemical equipment often needs to operate under high temperature, high pressure and corrosive environment. ERNiCrMo-3 welding wire has become the preferred welding material due to its good corrosion resistance and high temperature strength.

- Aerospace devices: Aerospace devices have extremely high requirements for welding quality. ERNiCrMo-3 welding wire can meet these requirements and ensure the safety and reliability of the device.

- Shipbuilding industry: The shipbuilding industry involves a large amount of metal welding work. ERNiCrMo-3 welding wire is widely used in the welding of hulls, marine equipment and other parts due to its good welding performance and corrosion resistance.

- Power industry: In the power industry, ERNiCrMo-3 welding wire is often used in the manufacturing and maintenance of power equipment such as generators and transformers to ensure the safe operation of the equipment.