Min. Order:100 Kilogram

Transportation:Ocean,Land,Air

$27.8≥100Kilogram

Brand: fenghua

Productivity: 8000t

Transportation: Ocean,Land,Air

Place of Origin: jiangsu

Supply Ability: 8000t

Certificate: iso9000

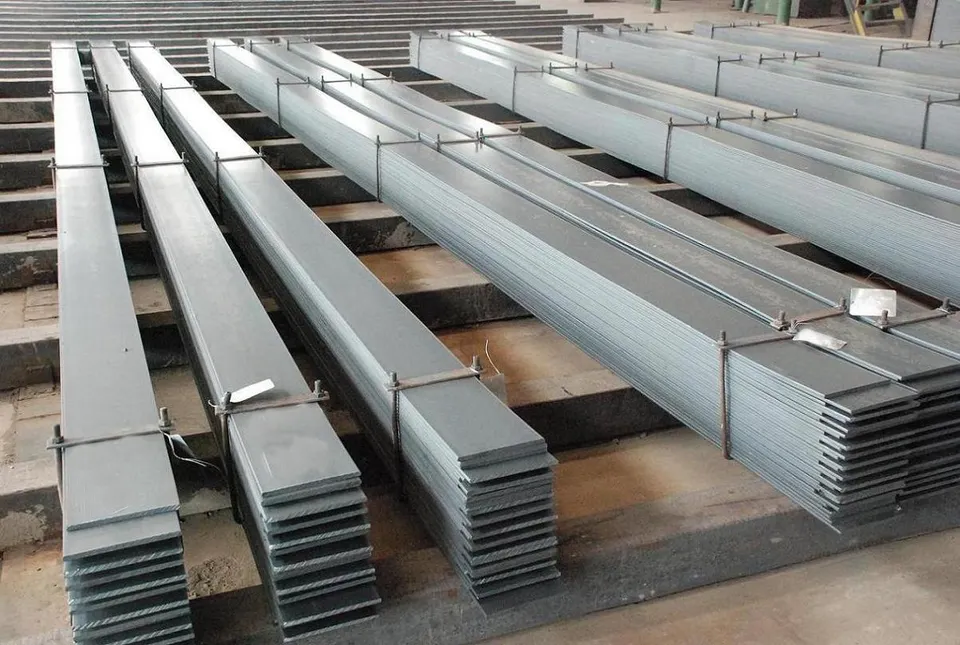

pecial alloy nickel inconel X-750 bar

The alloy X-750 also has outstanding mechanical properties down to cryogenic temperatures. With such properties, the nickel-chromium alloy is mainly used for high-temperature springs and bolts, gas turbine blades, rocket engines, abrasion wheels, high pressure vessels, etc.

Alloy X-750 has good resistance to corrosion and oxidation along with high tensile and creep-rupture properties at temperatures to about 1300°F (700°C). Alloy X-750 is used in applications such as gas turbines, jet engine parts, heat-treating fixtures, forming tools, and extrusion dies.

Alloy X-750 Specification

| UNS | W. Nr |

| N07750 | 2.4669 |

Alloy X-750 Chemical Compositions

| Composition | Ni | Cr | Fe | Nb | Co | C | Mn | Si | S | Cu | Al | Ti | P | |

| Content(%) | Min. | Bal. | 14 | 5.0 | 0.7 | | | | | | | 0.4 | 2.25 | |

| Max. | 17 | 9.0 | 1.2 | 1.00 | 0.08 | 1.00 | 0.50 | 0.01 | 0.5 | 1.0 | 2.75 | 0.02 | ||

Alloy X-750 Mechanical Properties (Minimum value at 20℃)

| Tensile Strength (σb/MPa) | Yield Strength (σp0.2/MPa) | Elongation (σ5/%) |

| 910 | 550 | 25 |

Alloy X-750 Standard

| Bar | Forging | Sheet/Strip | Wire |

| ASTM B637 | ASTM B637 | AMS 5542 AMS 5598 | AMS 5698 AMS 5699 |

| Other Nickel Alloy products | ||||

| Inconel | Incoloy | Monel | Hastelloy | Nimonic |

| Inconel 600 | Incoloy 800 | Monel 400 | Hastelloy X | Nimonic 75 |

| Inconel 601 | Incoloy 800H | Monel K500 | Hastelloy C276 | Nimonic 80A |

| Inconel 625 | Incoloy 800HT | Hastelloy B | Nimonic 90 | |

| Inconel 718 | Incoloy 825 | Hastelloy B2 | Nimonic 105 | |

| Inconel X-750 | Incoloy A286 | Hastelloy B3 | ||

| Inconel 660 | Incoloy 925 | |||

| Inconel 690 | ||||

| Pure Nickel | Precision Alloy | Other | Welding Material | |

| Nickel 200 | 1J50 | 904L | ERNi-1 | ER308 |

| Nickel 201 | 1J79 | Alloy 20 | ERNiCrMo-3 | ER308LSi |

| 1J85 | ERNiCr-3 | ER309 | ||

| 4J29 Kovar | ERNiCu-3 | ER309L | ||

| 4J36 Invar 36 | ERNiCrMo-4 | ER316 | ||

| Alloy 42 | ERNiFeCr-1 | ER316L | ||

| ERNiFeCr-2 | ER316LSi | |||

| ERNiCrFe-11 | ER385 | |||