Transportation:Ocean

Port:SHANGHAI

Model No.: 4J29 kovar forging

Place Of Origin: China

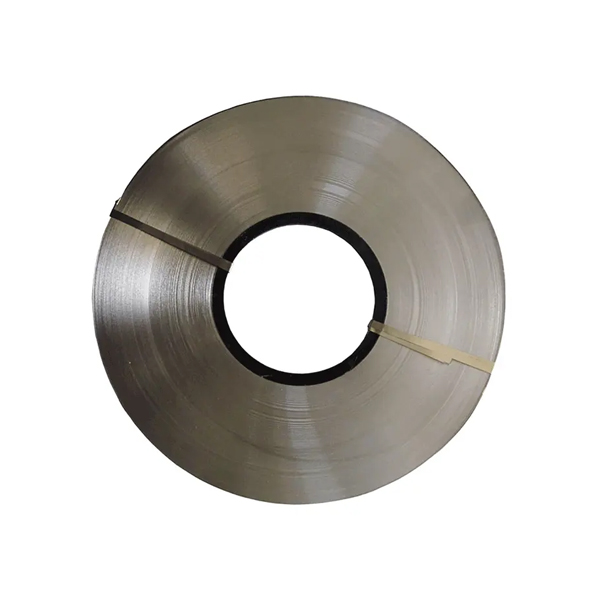

Packaging: We offer varied packaging in the form of coils, spools or as per customer required for 4J29 kovar forging

Transportation: Ocean

Place of Origin: CHINA

Supply Ability: 3000 Ton/Tons per Year for 4J29 kovar forging

Port: SHANGHAI

Nickel Alloy Precision 4J29 Kovar Forging

Size Range Beside, we can customize other specification as per your request

Kovar is a nickel-iron-cobalt alloy that has a very low coefficient of thermal expansion, making it ideal for use in electronic and electrical applications. 4J29 is a specific grade of Kovar that is commonly used in the manufacture of vacuum tubes, microwave tubes, and other electronic components.

Forging is a manufacturing process in which a metal is heated to a High temperature and then shaped by applying pressure with a hammer or press. Kovar forging involves heating the 4J29 Kovar alloy to a high temperature and then using a forging press to shape it into the desired form.

Kovar forging is a critical step in the manufacture of many electronic components, as it allows for precise shaping of the material to meet the exact specifications required for the application. Kovar forging also helps to improve the mechanical properties of the material, making it more durable and resistant to deformation under stress.

| Wire diameter: 0.02-12mm |

| Bar diameter: 10-300mm |

| Strip/ Coil 0.1-20mm Thick *1-250mm Width * unlimited Length |

| Sheet min o.7mm Thick * 1200mm Width max |

| Wielding wire 0.8mm, 1.0mm, 1.2mm, 2.0mm, 2.4mm, 3.2mm, 3.8mm, 4.0mm |

| Welding strip 0.4-0.7mm Thick * 25-60mm Width |

Kovar alloy is a iron-nickel-cobalt, low expansion alloy whose chemical composition is controlled

within narrow limits to assure precise uniform thermal expansion properties. Kovar alloy has been

used for making hermetic seals with the harder Pyrex glasses and ceramic materials.

Kovar Specification

| ASTM | UNS | W.Nr |

| F15 | K94610 | 1.3981 |

Kovar Chemical composition

| Grade | % | Ni | Cr | Fe | Co | Cu | C | Mn | Si | P | S | Mo |

| Kovar | Min | 28.5 |

| Bal. | 16.8 |

|

|

|

|

|

|

|

| Max | 29.5 | 0.2 | 17.8 | 0.20 | 0.03 | 0.50 | 0.30 | 0.02 | 0.02 | 0.20 |

Kovar Coefficient of linear expansion

| Grade | a/10-6·K-1 | ||

| Kovar | 200-300°C | 20-400°C | 20-450°C |

| / | 4.6-5.2 | 5.1-5.5 | |